Eco-Solvent Metallic WaterSlide Decal Paper

Product Detail

Eco-Solvent / UV WaterSlide Decal Paper

Eco-Solvent WaterSlide Decal Paper ( Clear, Opaque, Metallic ) that can be used by Eco-Solvent/UV printers and cutters, such as Mimaki CJV150, Roland TrueVIS SG3, VG3 and VersaSTUDIO BN-20, Mutoh XpertJet C641SR, Roland TrueVIS LG & MG, or label printing machine for all your craft projects. Personalize and customize your project by printing unique designs on our decal paper.

Transfer decals onto ceramics, glass, metal, painted wood, plastic materials and other hard surface. It is specifically designed for the decoration of all safety headwear, including motorcycle, winter sports, bicycle and skateboarding. or the logos brand owners of bicycle, snowboards, golf clubs and tennis rackets, etc.

Eco-Solvent / UV WaterSlide Decal Paper

Size: 50cm X 30M/Roll, 100cm X 30M/Roll, other specifications are required.

Inks: Eco-Solvent Max ink, UV ink, Latex ink

Printers: Eco-Solvent / UV printers and cutters, or printers and cutters dual

Advantages

■ Compatible with Eco-Solvent / UV Printers and Cutters, or Printers and Cutters dual

■ Good ink absorption, color retention, and print stability, consistent cutting

■ Transfer decals onto Ceramics, Glass, Metal, Painted wood, Plastic materials and other hard surface

■ Good thermal stability and weather resistance

■ At 500 °C temperatures, combusts with virtually no residue, especially suitable as a temporary carrier for ceramic inks

Mimaki Eco-Solvent Inkjet Printers and Cutters for Safety Helmets

what can you do for your craft projects ?

Motorcycle Parts and Helmet Series :

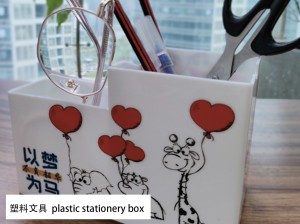

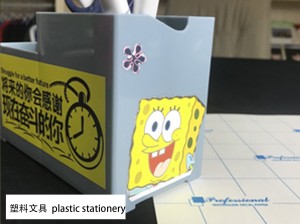

Plastic Products :

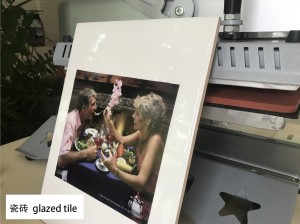

Ceramic Products :

Glass Products :

Metal Products :

Wood Products :

Product Uasge

3. Printer Recommendations

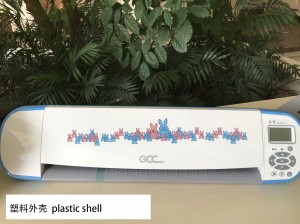

Eco-Solvent Printers and Printers/Cutters: (Mutoh) XpertJet C641SR Pro, (Roland) VersaSTUDIO BN2 Series TrueVIS SG3/VG3, ( Mimaki ) print & cut CJV200 Series/

UV Printers and Printers/Cutters: Mimaki UCJV, Roland TrueVIS LG and MG series

4. Water-slip transferring

step 1. Print patterns by Eco-Solvent/UV printers

step 2. Cut patterns by vinyl cutting plotters

step3. Submerge you pre-cut decal in 35~55degree water for 30-60 seconds or until the middle of the decal can easily easily slide around. Remove from water.

step 4. Quickly apply it to your clean decal surface then remove the carrier gently behind the decal, squeeze the images and remove the water and bubbles from the decal paper.

step 5. Let the decal set and dry for at least 48 hours. Don’t expose to direct sunlight during this time.

step 6. Spraying car clearcoat for better gloss, hardness, scrub resistance.

Note: If you want better gloss, hardness, washability, etc., you can use polyurethane varnish, acrylic varnish, or UV-curable varnish to spray coverage protection.

It is preferred to spray automotive varnish to obtain better gloss, hardness, and scrub resistance

6. Finishing Recommendations

Material Handling & Storage: conditions of 35-65% Relative Humidity and at a temperature of 10-30°C.

Storage of open packages: When an open packages of media is not being used remove the roll or sheets from the printer cover the roll or sheets with a plastic bag to protect it from contaminants, if you are storing it on end, use an end plug and tape down the edge to prevent damage to the edge of the roll do not lay sharp or heavy objects on unprotected rolls and do not stack them.