Inkjet print and cut Transfer Paper HTW-300R and Pure Color Heat Transfer Vinyl PU Flex Regular CCF-R

Product Detail

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for Inkjet print and cut Transfer Paper HTW-300R and Pure Color Heat Transfer Vinyl PU Flex Regular CCF-R, With excellent services and good quality, and an enterprise of foreign trade featuring validity and competitiveness, that can be trusted and welcomed by its customers and generates happiness to its staff.

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for China htv rolls heat transfer vinyl and htv heat transfer vinyl rolls, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Remember to your inquiry for more details or request for dealership in selected regions.

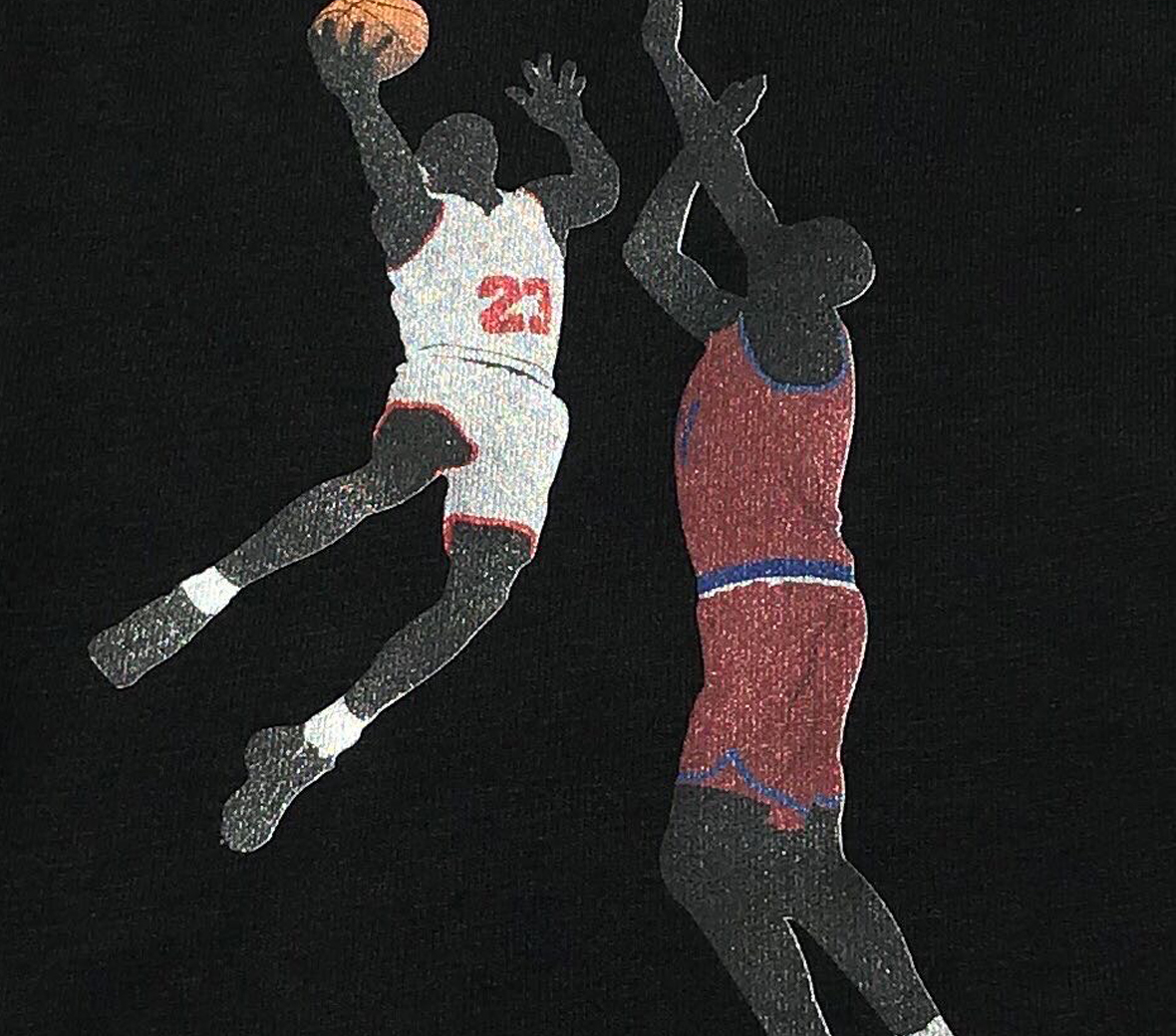

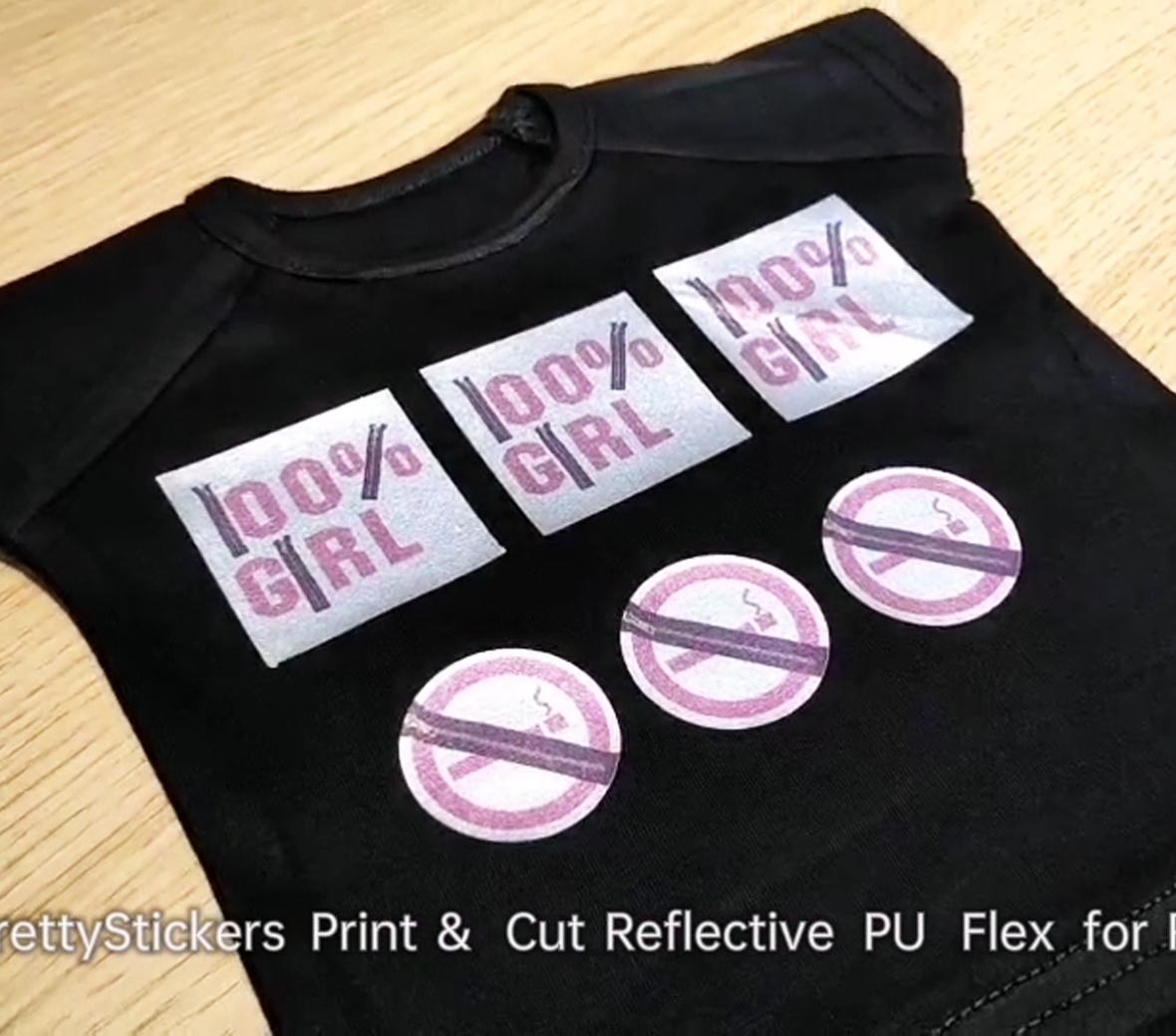

Eco-Solvent Printable Reflective PU Flex

Eco-Solvent Printable Reflective Heat Transfer PU Flex can be printed by all kinds of Eco-Solvent inkjet printers such as Roland Versa CAMM VS300i, VersaStudio BN20 etc, get great durability with image retaining color, wash-after-wash. Decorate fabric with photos in minutes. Innovative hot melt adhesive is suitable to transfer onto textiles like cotton, mixtures of polyester/cotton and polyester/acrylic, Nylon/Spandex etc. by heat press machine. It is ideal for customizing dark, or light colored T-shirts, canvas bags, sport & leisure wear, uniforms, biking wear, promotional articles and more. with the reflective metallic back of printable PU Flex, after printing & transferring, Increase color and increase visibility

Advantages

■ Customize fabric with favorite photos and color graphics.

■ Designed for vivid results on dark, white or light-colored cotton or cotton/polyester blend fabrics

■ Ideal for personalizing T-shirts, canvas bags, canvas bags, uniforms, photographs on quilts etc.

■ Good washable and keep coloration

■ More flexible and more elastic

■ Ideal for fine cutting and cutting consistent

View Printable Reflective video

More Application

You can transfer by Inkjet print and cut Transfer Paper HTW-300R that printed by any inkjet printers with normal dye, or pigment ink, such as Epson L805, photo 1390, Canon ix4800 etc.

and Alizarin Pure Color Heat Transfer Vinyl PU Flex Regular CCF-R with desk vinyl cutting plotter such as Alizarin Panda mini cutter, Silhouette CAMEO, Circuit. etc.

More info, please click the whatsapp link https://wa.me/8613506998622 to chat. or send by mail: sales@alizarin.com.cn

Thanks and Best Regard

Ms. Tiffany

Alizarin coating Co., Ltd.

TEL: 0086-591-83766293/83766295

FAX: 0086-591-83766292

WEB: https://www.AlizarinChina.com/

ADD: 901~903, NO.3 building, UNIS SCI-TECH Park, Fuzhou High-Tech Zone, Fujian, China.

#heattransfervinyl #vinylcutter #transferpaper #cameo4 #cricut #rolandbn20 #mimaki #inkjettransferpaper #printablevinyl #alizarin #inkjetprinters #printableflock #printableglitter #phototransferpaper

Product Uasge

3.Printer Recommendations

It can be printed by all kinds of Eco-Solvent inkjet printers such as : Roland Versa CAMM VS300i/540i, VersaStudio BN20, Mimaki JV3-75SP, Uniform SP-750C, and other Eco-solvent inkjet printers etc.

4.Heat press transferring

1). Setting a heat press at 165°C for 25 seconds using moderate pressure.

2). Briefly heat the fabric for 5 second to ensure that it is completely smooth.

3). Leave the printed image to dry for approx.5 minutes, cut out the image around the edges. Peel the image line off from the backing paper gently by adhesive polyester film.

4). Place the image line facing upwards onto the target fabric

5). Place the cotton fabric onto it.

6). After transferring for 25seonds , move away cotton fabric, then cooling for about several minutes, Peel the adhesive polyester film starting at the corner.

5.Washing Instructions:

Wash inside out in COLD WATER. DO NOT USE BLEACH. Place into the dryer or do hang to dry immediately. Please do not stretch the image transferred or the T-shirt as this may cause cracking to occur, If cracking or wrinkling does occur, please place a sheet of greasy proof paper over the transfer and heat press or iron for a few seconds making sure to press firmly over the entire transfer again. Please remember to not iron directly on the image surface.

6.Finishing Recommendations

Material Handling & Storage: conditions of 35-65% Relative Humidity and at a temperature of 10-30°C.

Storage of open packages: When an open packages of media is not being used remove the roll or sheets from the printer cover the roll or sheets with a plastic bag to protect it from contaminants, if you are storing it on end, use an end plug and tape down the edge to prevent damage to the edge of the roll do not lay sharp or heavy objects on unprotected rolls and do not stack them.