Eco-Solvent Printable Vinyl

Product Detail

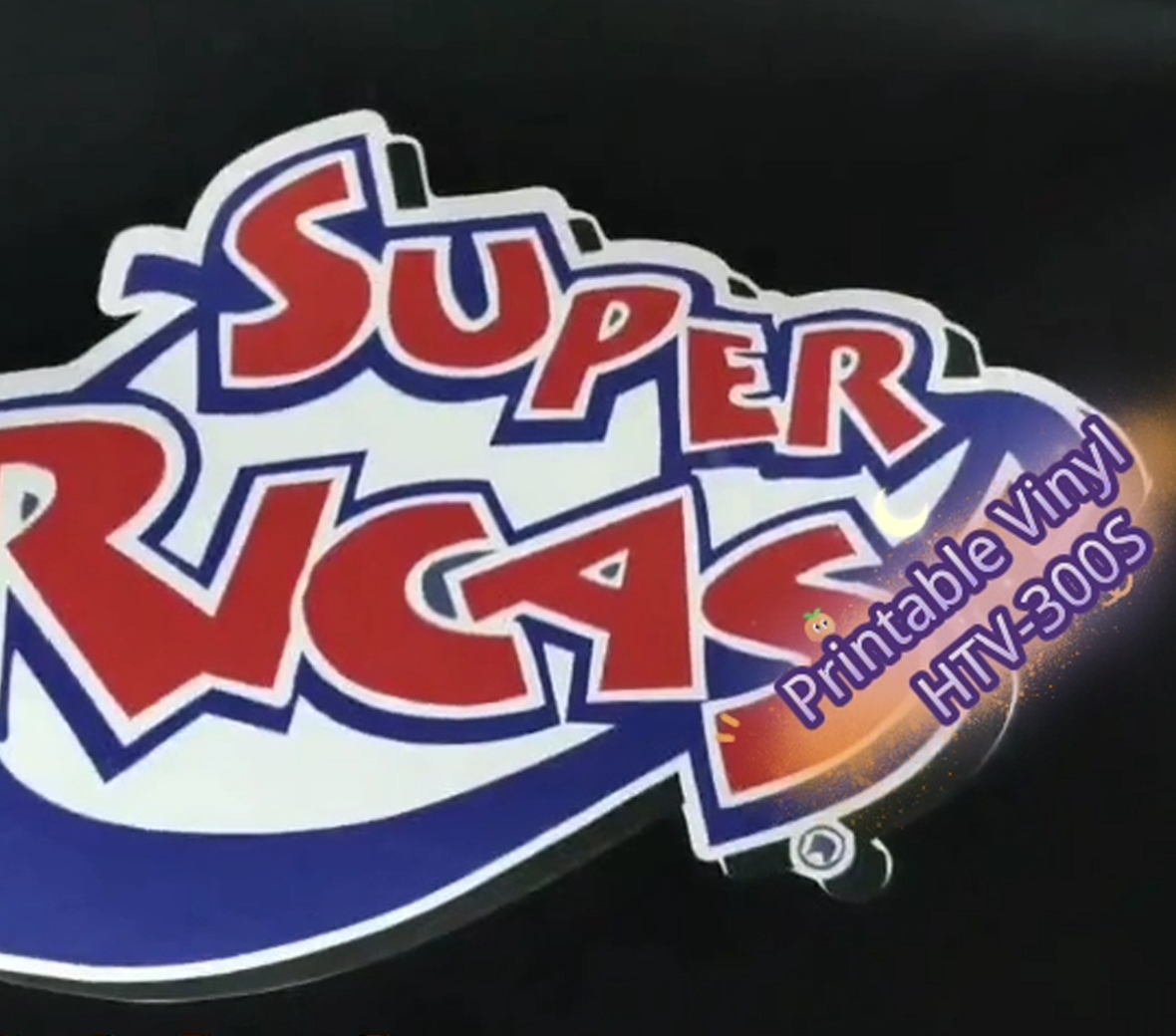

3D UV / Eco-Solvent Printable Vinyl ( HTV-300S )

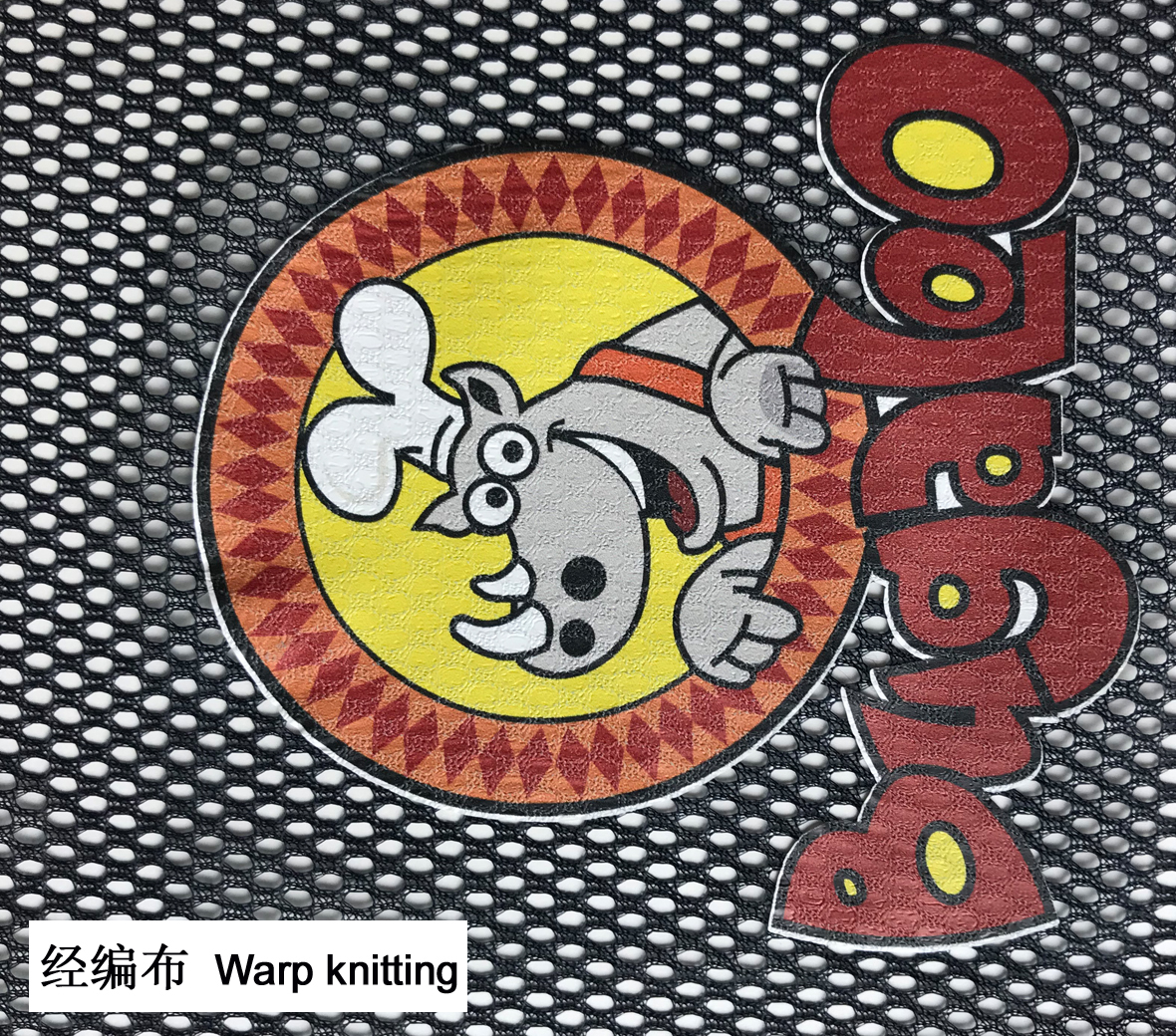

3D UV / Eco-Solvent Printable Vinyl ( HTV-300S ) is based polyvinyl chloride film that produced according to the EN17 standard. It is with hot melt adhesive on 100 micron thickness polyester film line with antistatic treated, which can prevent static electricity during use effectively, Innovative hot melt adhesive is suitable to transfer onto textiles like cotton, mixtures of polyester/cotton, polyester/acrylic, Nylon/Spandex and coated leather,EVA foamed etc.

The thickness of the Printable Vinyl Flex is 180 / 280 /550 microns, which is especially suitable for heat transferring on rough fabrics, wooden boards, leather, etc. It is an ideal material for jerseys, sport & leisure wear, biking wear, labor uniforms, foamed leather and shoes, skateboards, and bags, etc. Excellent cutting and weeding properties. Even detailed logos and extremely small lettering are cut table.

Specifications: 50cm X 30M, 100cm X30M/Roll,

Ink Compatibility: Eco-Solvent Max ink, Mimaki CJV150 BS3/BS4 ink, UV ink, Latex ink

Printers : UV / Eco-Solvent printers and cutters Roland VS300i, Mimaki CJV;

UV/ Eco-Solvent inkjet printers and Vinyl cutting plotters dual

Advantages

■ Compatible with Eco-Solvent ink, UV ink, and Latex ink

■ High printing resolution up to 1440dpi, with bright colors and good color saturation!

■ Designed for vivid results on 100% cotton, 100% polyester, cotton/polyester blend fabrics, artificial leather etc.

■ Ideal for personalizing T-shirts, jerseys, canvas bags, uniforms, photographs on quilts etc.

■ Excellent machine washing, and with good color retention

■ 180 thickness flex, idea for rough leather, fabric rough, without background color visible

■ Ideal for fine cutting and cutting consistent

Eco-Solvent Printable Vinyl

Numbers and Logos of Football Uniform with Printable Vinyl (HTV-300S)

Applicable printers and inks

what can you do for your Clothing and decorative fabrics projects ?

Transfer onto all kinds of fabric

Product Uasge

Basic characteristics

Printer recommendations

|

Eco-Solvent ink |

UV ink |

Latex ink |

| Mimaki CJV150, Roland VS300i | Roland LG | HP Latex 315 |

|

|

|

|

Step by step: UV/Eco-Solvent Printing, Heat transferring

step1. Print patterns by UV/Eco-Solvent/Latex printers

step2.Cut patterns by Laser cutting plotters

step3. Weeding and laminate with adhesive film

Step4. Place the image line facing upwards onto the target fabric laminate with adhesive film

Step 5. Setting a heat press at 165°C for 25 seconds using moderate pressure.

step 6. Peel the adhesive polyester film starting at the corner.

step 7. Finished.

Finishing recommendations

Material Handling & Storage: conditions of 35-65% Relative Humidity and at a temperature of 10-30°C.

Storage of open packages: When an open packages of media is not being used remove the roll or sheets from the printer cover the roll or sheets with a plastic bag to protect it from contaminants, if you are storing it on end, use an end plug and tape down the edge to prevent damage to the edge of the roll do not lay sharp or heavy objects on unprotected rolls and do not stack them.