Subli-flock transfer paper

Product Detail

Eco-Solvent Subli-Flock HTF-300S with Sublimation Paper for 100% cotton Fabric

This is Sublimation-Flock HTF-300S produced by our company. At first, print on sublimation transfer paper by Epson L805 with sublimation ink. then, Heat transfer the pattern of the sublimation transfer paper to Sublimation -Flock HTF -300S by heat press machine with 165°C and 15~25 second,third, cutting by a cutting plotter such as: Silhouette CAMEO4, Cricut,Finally, the flocked Sublimation-Flock HTF -300S onto 100% cotton, polyester-cotton blended fabrics by heat transfer machine.

The outstanding features of this product: bright colors, fluffy texture, excellent washability.

Advantages

■ Bright colors and washable.

■ Flocking surface texture.

■ It can print and transferred a variety of fabrics, such as 100% cotton, polyester-cotton blends, etc.

■ Transferred by heat press machine, or home iron.

Subli-Flock (HTF-300S) with Sublimation Paper for 100% cotton T-shirts

Step 1. Design the printable pictures, and cuttable pictures, printing the pictures by Epson L805 with sublimation ink to sublimation transfer paper

Step 2. Align the pattern side of the sublimation transfer paper with the flocking side, and the sublimation transfer paper on top, the pattern of the sublimation transfer paper transfer to the Sublimation-Flock HTF-300S by heat press machine with 165°C and 15~25 seconds.

Step 3. Cutting by a desk vinyl cutter such as #Cricut, #Cameo4, #Panda Mini Cutter, Brother #ScanNcut

Step 4. Transfer Sublimation-Flock HTF -300S to the clothes by heat press machine with 165°C and 15~25 seconds.

what you can do for your Clothing and decorative fabrics projects ?

Product Uasge

4. Sublimation Printer Recommendations

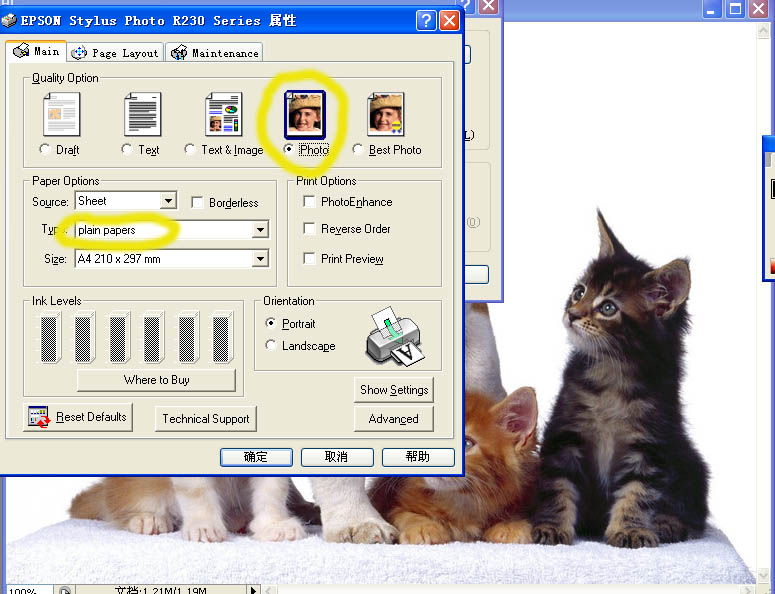

It can be printed with most piezo inkjet printers (changed to sublimation inks) such as: Epson Stylus Photo 1390, R270, R230, L805, etc.

5. Sublimation Printing setting

Quality Option: photo(P), Paper Options: Plain papers. and the printing inks is sublimation ink.

6. The process of sublimation paper printing and heat transfer

a. Make a vector diagram with the positioning marks of the cutting plotter and a vector outline diagram of the cutting marks.

b. Use a sublimation ink printer to print the vector image (mirror print) onto the sublimation paper.

c. Put the image side of the printed sublimation paper and the fleece side of the flocking paper together, and place them on the heat press machine with the sublimation paper facing up.

d. Set the temperature of the heat press machine at 165°C, medium pressure, and time 35~45 seconds. After the sublimation transfer is completed, tear off the sublimation paper while it is still hot.

e. After the flocking paper is transferred, it is completely cooled for about 30 minutes, and the excess white edge is cut off with a cutting machine. Remove the flock by hand or with transfer paper.

f. Put the clothes flat on the bottom plate of the heat press machine, and iron them for 5 seconds.

g. Gently place the flocking film on top of the garment, pattern side up. Cover with a piece of greaseproof paper or transfer paper, and cover with a cotton cloth.

h. At 165°C, press the heat transfer machine for 15~25 seconds.

i. Peel off the greaseproof or transfer paper. Finish!

7.Washing Instructions:

Wash inside out in COLD WATER. DO NOT USE BLEACH. Place into the dryer or do hang to dry immediately. Please do not stretch the image transferred or the T-shirt as this may cause cracking to occur, If cracking or wrinkling does occur, please place a sheet of greasy proof paper over the transfer and heat press or iron for a few seconds making sure to press firmly over the entire transfer again.Please remember to not iron directly on the image surface.

8.Finishing Recommendations

Material Handling & Storage: conditions of 35-65% Relative Humidity and at a temperature of 10-30°C.Storage of open packages: When an open packages of media is not being used remove the roll or sheets from the printer cover the roll or sheets with a plastic bag to protect it from contaminants, if you are storing it on end, use an end plug and tape down the edge to prevent damage to the edge of the roll do not lay sharp or heavy objects on unprotected rolls and do not stack them.