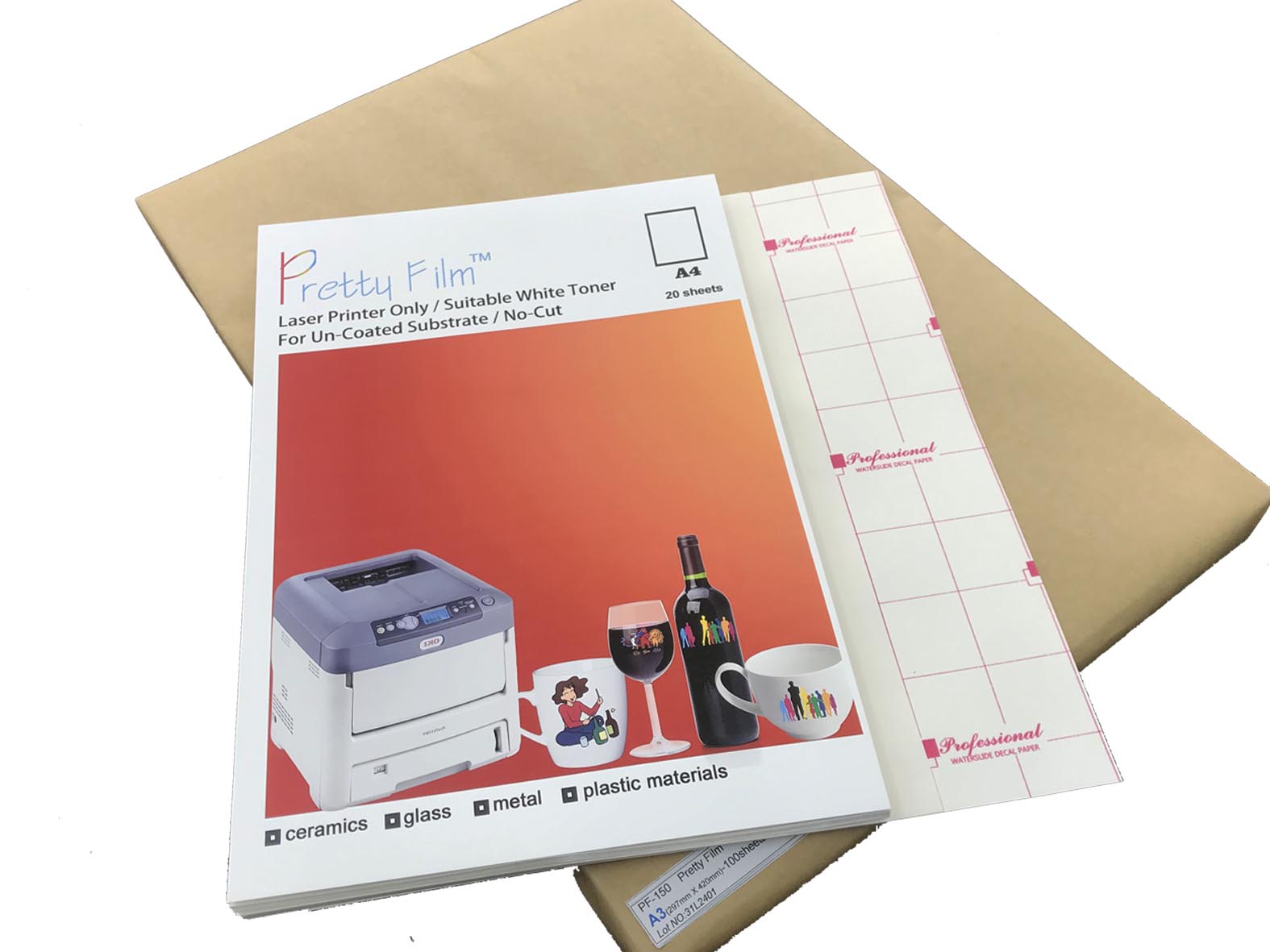

Pretty-Film (PF-150)

Original toner Only, Low-temperature baking!

Pretty-Film (PF-150) printed by color laser printers, or color laser copy printers with flat feed and flat output, such as RICOH IM C2001、C300F、Aficio SP C840DN for all your Ceramic cups/mugs/tea cups. pre-treatment of FJ5 with images to ensure proper ink adhesion, then water slide decals onto un-coated Ceramic cups, After baking in an electric oven at 130°C~145°C for about 5~10 minutes, After cooling to room temperature, tear off the surface film to get the finished product. The outstanding features of the Pretty-Film are that it does not require pre-coating, and No-Cut. It is also heat-resistant, weather-resistant and washable.

Product Description:

Product name: PF-150

Product name: Pretty -Film

Main specifications:

A4 (210mm X 297mm) – 100 sheets/pack,

A3 (297mm X 420mm) – 100 sheets/pack,

33cm X 300 meter /roll,

Laser Printers: Color laser printer with flat paper input and flat paper output is preferred,

Main Features:

■ Genuine toner ONLY, low-temperature baking.

■ Print from one sheet, no plate making required.

■ No Pre-coating required, finished product can be hollowed out.

■ Capable of overprinting on curved surfaces, arcs, and corners.

■ Heat-resistant, weather-resistant, and washable.

RICOH IM C2001 for printing on ceramic

Step by step:water slide to baking

step 1. Laser printing:

The printing settings of laser printers of different brands and models are not exactly the same. Please read the operating instructions of the laser printer carefully or consult the laser printer sales agent for laser printing settings.

step 2. Pre-coating:

Soak a sanitary napkin in the Pre-Coat FJ5 pre-treatment liquid and gently wipe the laser-printed coating surface. Let it dry naturally for about 5 minutes.

Note: There should be no water droplets. If there are any, wipe them dry with a dry cotton ball.

step 3. Water slide:

Soak in warm water (water temperature is about 50~60 °C) for about 30~60 seconds, until the Pretty-Film (PF-150) can be easily separated from the based paper.

step 4. Remove bubbles

With the printed surface facing down, press the backing paper to separate it from the film, leaving the film on the glasses product. Press the film and gently slide it to a suitable position. Use a rubber melon or a wet towel to gently scrape the water droplets and bubbles between the film and the craft product.

step 5. baking:

Set the electric baking temperature to 130°C~145°C and the time to 5~10 minutes. The optimal temperature and time can only be determined after multiple tests.

Glass products need to be heated up slowly to the required temperature to avoid sudden temperature changes and spontaneous explosion of the glass.

Put the ceramic cup in the electric oven, close the door, and adjust the time knob to 5~10 minutes. When the baking time is reached, open the oven door, put on high-temperature resistant gloves, take out the ceramic cup, and place the cup on a heat-resistant table.

step 6. Film tearing:

Let it cool naturally for about 30~60 minutes and start to tear off the film from the corners.

Please do not try to scrape, rub or pick at the finished product, as it needs to be left for at least 24 hours to achieve the best fastness.

For more application scenarios, please visit https://www.alizarinchina.com/pretty-film-3-product/, or contact with

Mr. Henry

e-mail: cc@alizarin.com.cn

whatsapp: https://wa.me/8613599392619

or

Ms. Sunny

e-mail: pro@alizarin.com.cn

whatsapp: https://wa.me/8613625096387

Alizarin Technologies Inc.

TEL: +86-591-83766293/83766295

FAX: +86-591-83766292

WEB: https://www.AlizarinChina.com/

ADD: 901~903, NO.3 building, UNIS SCI-TECH Park, Fuzhou High-Tech Zone, Fujian, China

Post time: Aug-22-2025

3-300x225.jpg)