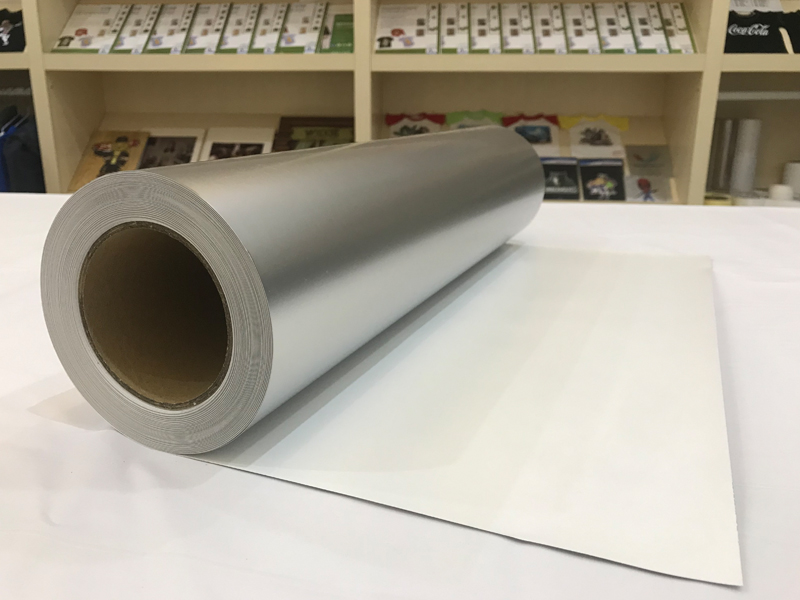

Printable Heat Transfer Decal Metallic Foil

Product Detail

Printable Heat Transfer Decal Metallic Foil

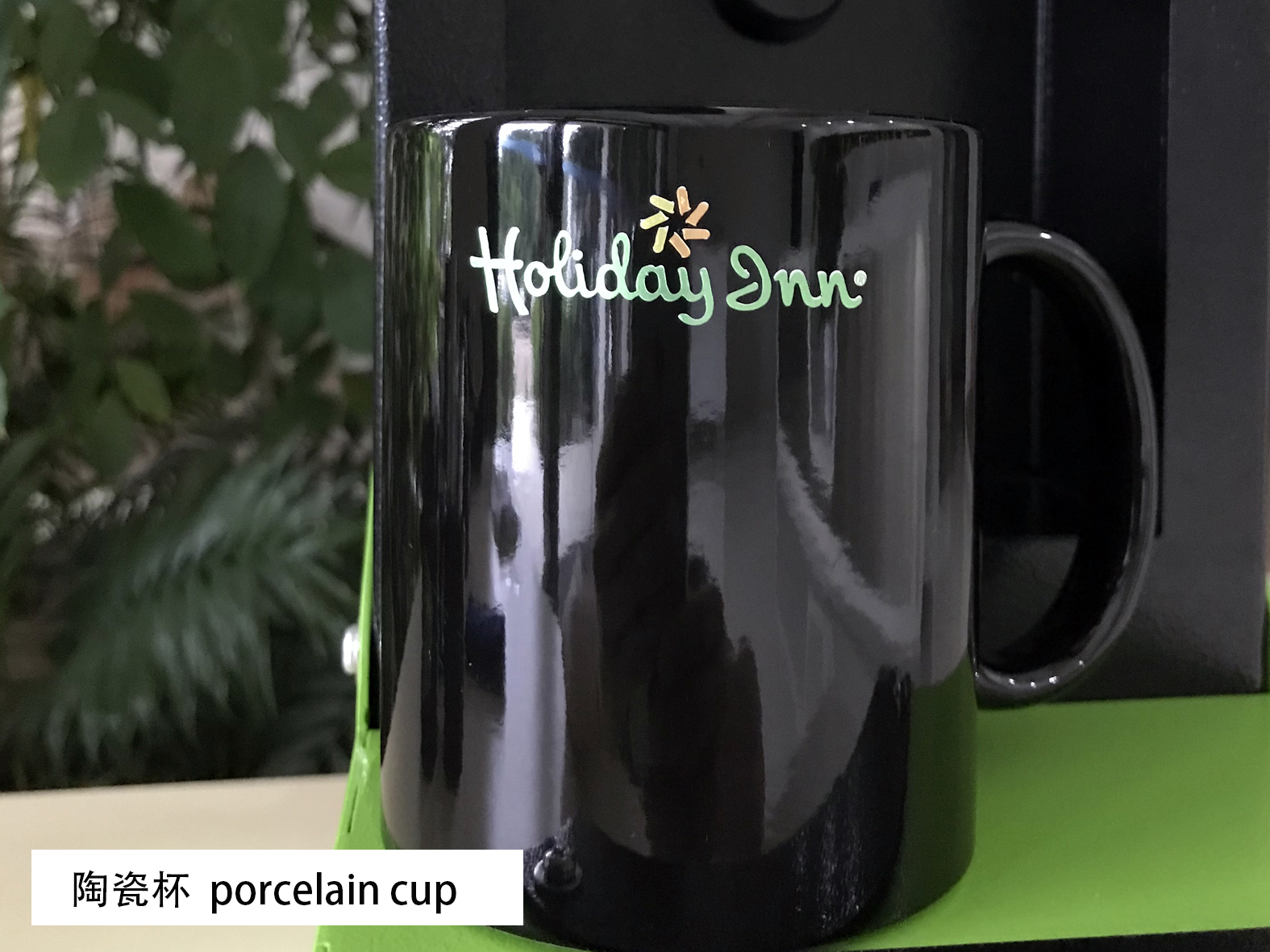

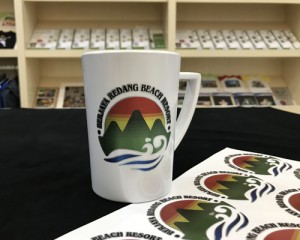

Eco-Solvent Printable Heat Transfer Decals Foil are our patented product that can be used by Eco-Solvent printers and cutters, such as Mimaki CJV150, Roland Versa CAMM VS300i, Versa Studio BN20, for all your craft projects. Personalize and customize your project by printing unique designs on our decal foil. Transfer decals foil onto No surface treatment (un-coated) ceramic tile, marble, porcelain cup, ceramic mug, Plexiglass glass, stainless steel thermos cup, tempered glass, crystal stone, Aluminum plate, metal, plastic materials and other hard surface.

Advantages

■ Exclusive metallic colors

■ No surface treatment (un-coated), unlimited base color

■ Compatibility with Eco-Solvent Max ink, UV ink, and Latex ink, etc.

■ Good ink absorption, and color retention

■ Compatibility with Eco-Solvent Printers and Printers/Cutters,

■ Ideal for print stability, and consistent cutting

■ Transfer decals onto ceramics, glass, jade, metal, plastic materials and other hard surfaces

■ Good thermal stability and weather resistance

Printable Heat Transfer Decal Metallic Foil (HSFS-300S) processing video

what you can do for your craft projects ?

Heat Transfer Decals Foil for Ceramic Products :

Heat Transfer Decals Foil for Plastic Products :

Heat Transfer Decals Foil for Metal Products :

Heat Transfer Decals Foil for Glass Products :

Product Uasge

Printer recommendations

|

Eco-Solvent ink |

UV ink |

Latex ink |

| |

|

|

Heat Press Machine

|

Roller heat press |

Mug heat press |

Roller heat press |

| |

|

|

Step by step Heat Transfer

step1. Print patterns by Eco-Solvent printers

step2.Cut patterns by vinyl cutting plotters

step3. Peel the image line off from the backing paper, then gently by adhesive polyester film, Place the image line facing upwards onto the target ceramic cup

4. Transferred by Cup heat press machine with 165°C and 120 second

5. peel off the adhesive polyester film with warm or cold

Cup & Roller Heat Press

|

|

Mug heat press |

Roller heat press |

Flatbed heat press |

|

Porcelain cup |

155 ~ 165°C X 60sec |

155 ~ 165°C X 60sec, 3cycle |

155 ~ 165°C X 60sec |

|

Plastic cup |

155 – 165°C X 35sec |

155 ~ 165°C X 60sec, 3cycle |

155 – 165°C X 35sec |

|

Aluminum cup |

155 – 165°C X 35sec |

155 ~ 165°C X 60sec, 3cycle |

155 – 165°C X 35sec |

The information contained herein is believed to be reliable, but no representations, guarantees or warranties of any kind are made as to its accuracy, suitability for applications or the results to be obtained. The information is based on laboratory work with small-scale equipment and does not necessarily indicate product performance. Because of the variations in methods, conditions and equipment used commercially in processing these materials, no warranties or guarantees are made as to the suitability of the products for the applications disclosed. Full-scale testing and product performance are the responsibility of the user.

Finishing recommendations

Material Handling & Storage: conditions of 35-65% Relative Humidity and at a temperature of 10-30°C.

Storage of open packages: When an open packages of media is not being used remove the roll or sheets from the printer cover the roll or sheets with a plastic bag to protect it from contaminants, if you are storing it on end, use an end plug and tape down the edge to prevent damage to the edge of the roll do not lay sharp or heavy objects on unprotected rolls and do not stack them.