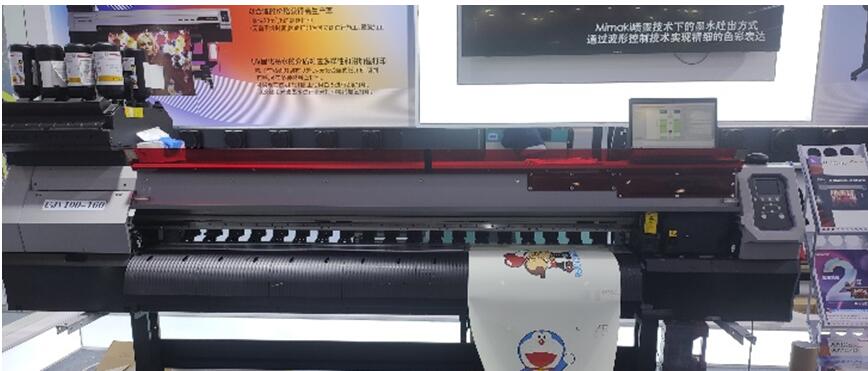

Application Examples of UJV 100-160:

1.Who can benefit from reading this document?

This document is intended for:

Owners and operators of any MIMAKI UJV Printer, with special focus on theMAMAKI UJV 100-160 Printer & series printers.

MIMAKI UJV customer support, marketing and sales organizations.

Front-end Development and sales of young Fashion Fast Consumer goods

This document provides information about:

The process to transfer a “heat transfer material”with glow in dark effects to clothing, including printing on an MMAKI UJV Printers, the cutting with a contour cutter, weeding the excess of material and transferring the material to the fabric.

A list of heat transfer materials that have been tested to guarantee good printability and good transfer to the fabric.

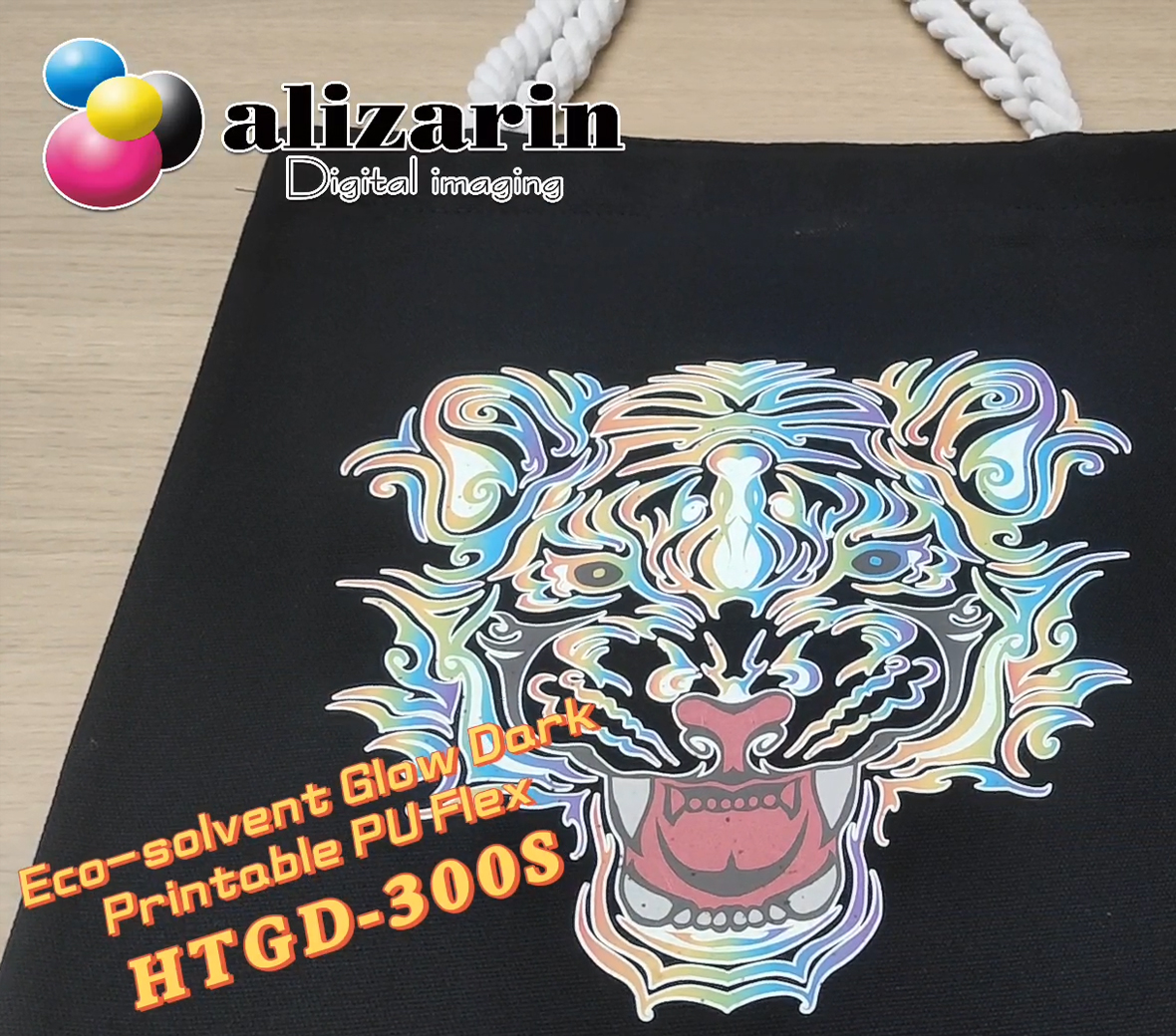

With photo-Chromic material line with glow in dark up to 8 hours

2. Introduction to “Customized Glow in Dark Clothing”

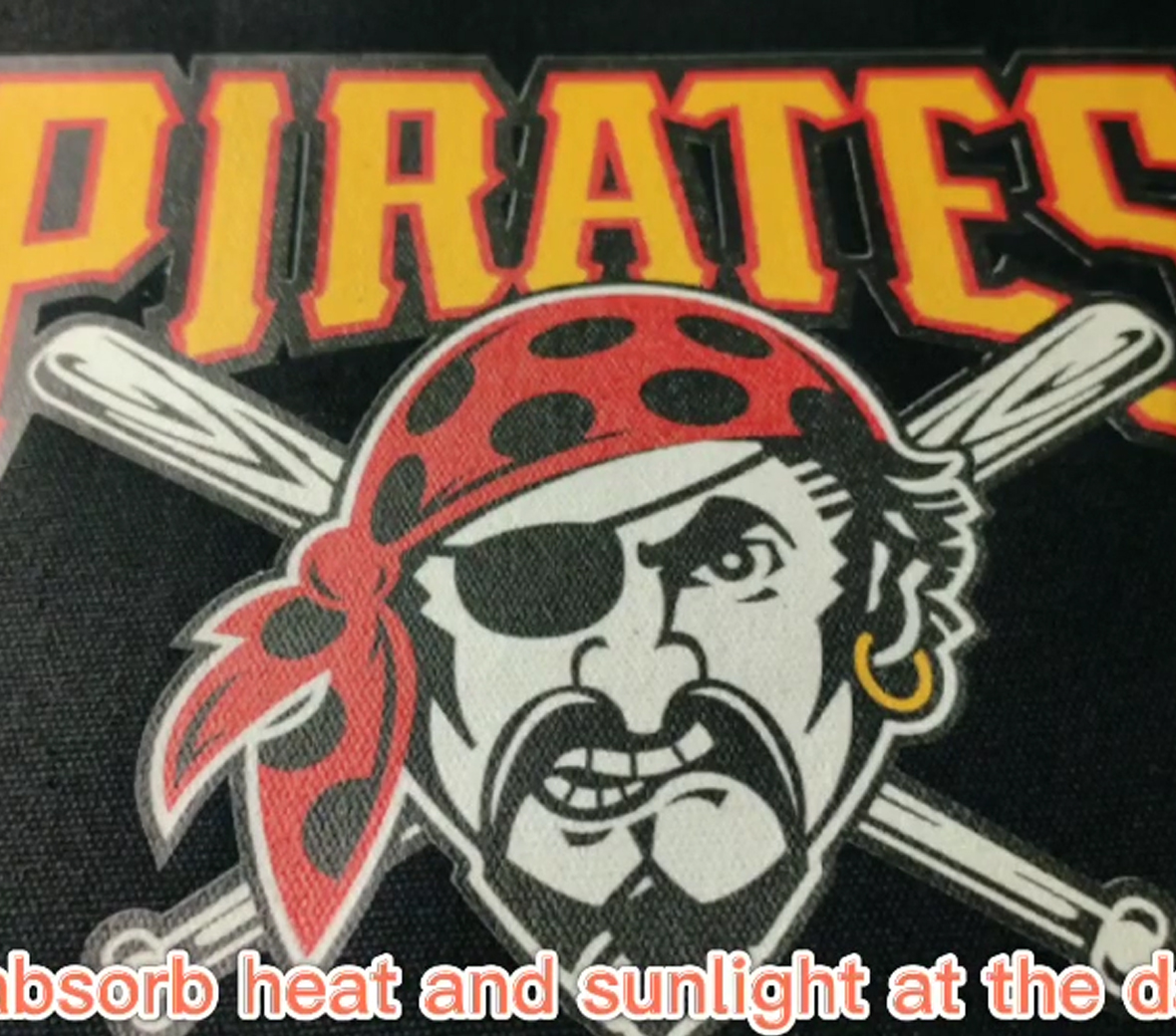

MIMAKI UJV printers are one of the best choices for customizing market. It can print on standard printers and cutters heat transfer PU materials in the inkjet printing market. Alizarin Prettystickers produced by Alizarin Technologies is developed and manufactured for printers with solvent ink, solvent ink, Eco-Solvent Max ink, latex ink, and UV ink. etc.) . HTGD-300S Eco-solvent Glow Dark Printable PU Flex Heat Transfer Vinyl has attracted tremendous attentions in the customized and safety markets. This material will be printed with MIMAKI UJV printer or an eco-solvent printer and run through a contour cutter by the MAMAKI contour cutting machine.

With the innovative hot-melt adhesive, there is no need to worry about specific fabric such as cotton, polyester/cotton and polyester/acrylic, nylon/spandex, etc. by means of a heat press. Customized Glow in Dark Clothing is ideal for customizing dark or light T-shirts, canvas bags, leisure wear, uniforms, cycling wear, festival clothing, promotional items and more. The outstanding features of this product are fine cutting, consistent cutting and excellent washing resistance.

The cut material is then ready to be transferred to fabric: this is usually done with an “adhesive polyester film”, which allows for the different pieces to keep its relative position, as well as to be placed on the right side for the transfer. The adhesive polyester film is placed onto the fabric and the hot press is run with the right specifications determined from each media vendor in their corresponding

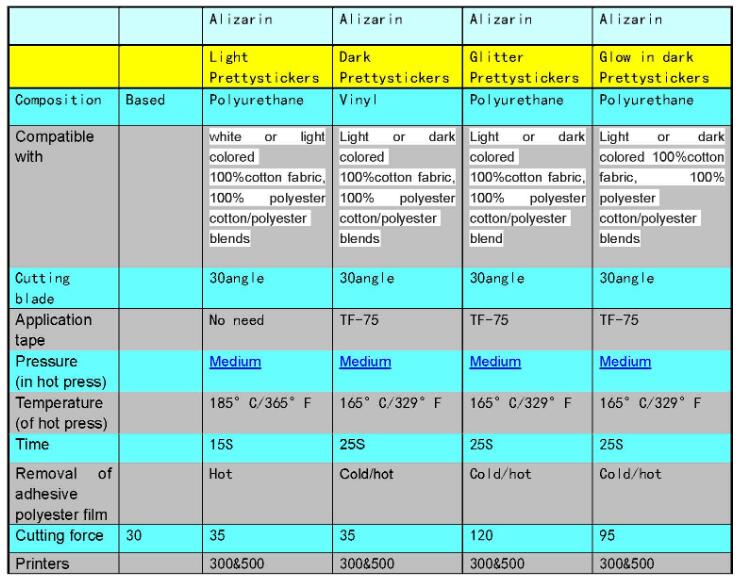

3.Certified heat transfer materials

Here is a table with information on how to use these materials. More updated and specific information can be obtained at https://www.alizarinchina.com/eco-solvent-printable-flex/

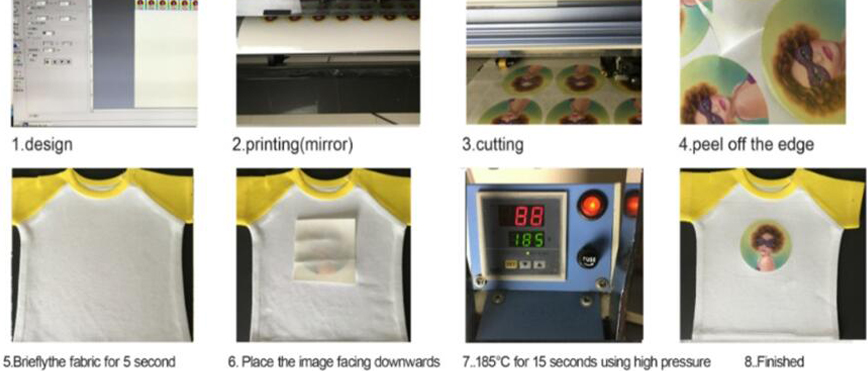

4.How to make a customized T-shirt with light Eco-Solvent Printable Flex

1.Setup graphics to MIMAKI UJV printer and print- with correct cut line(mirror printing )

2.Print graphics with a heat transfer material and cut with large format contour cutter

3.Remove excess media from carrier

4.Pre-press garment(White or light textiles only) for 2-3 seconds.

5.Position graphics on garment with facing down

6.Heat press on medium pressure at 185 °C for 15seconds

7.Peel off carrier with hot

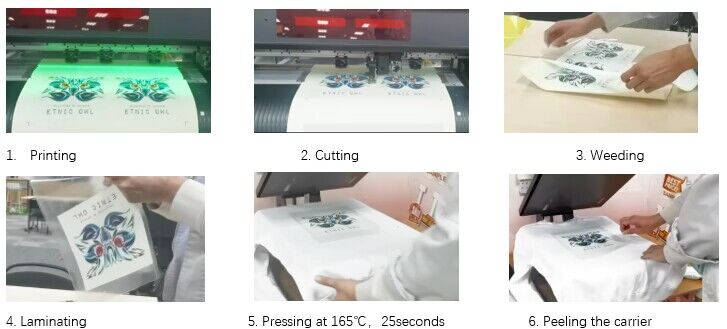

5.How to make a customized T-shirt with dark Eco-Solvent Printable Flex

1.Setup graphics to MIMAKI UJV printer and print- with correct cut line

2.Print graphics with a heat transfer material and cut with large format contour cutter

3.Remove excess media

4.Apply adhesive polyester film over top

5.Remove motifs from carrier

6.Pre-press garment(black and color textiles)for 2-3seconds

7.Position motifs on garment

8.Heat press on medium pressure at 165 °C for 25 seconds

9.Allow to peel off carrier cool or hot

10.Re-press using Teflon cover sheet for 3-5 seconds

to know more, please visit https://www.alizarinchina.com/eco-solvent-glow-dark-printable-pu-flex-product/,or contact with Ms Tiffany by WhatsApp https://wa.me/8613506998622 ,by e-mail:sales@alizarin.com.cn for free samples.

Best Regard

Ms. Tiffany

Alizarin Technologies Inc.

TEL: 0086-591-83766293/83766295

FAX: 0086-591-83766292

WEB: https://www.AlizarinChina.com/

ADD: 901~903, NO.3 building, UNIS SCI-TECH Park, Fuzhou High-Tech Zone, Fujian, China.

Post time: Mar-10-2023